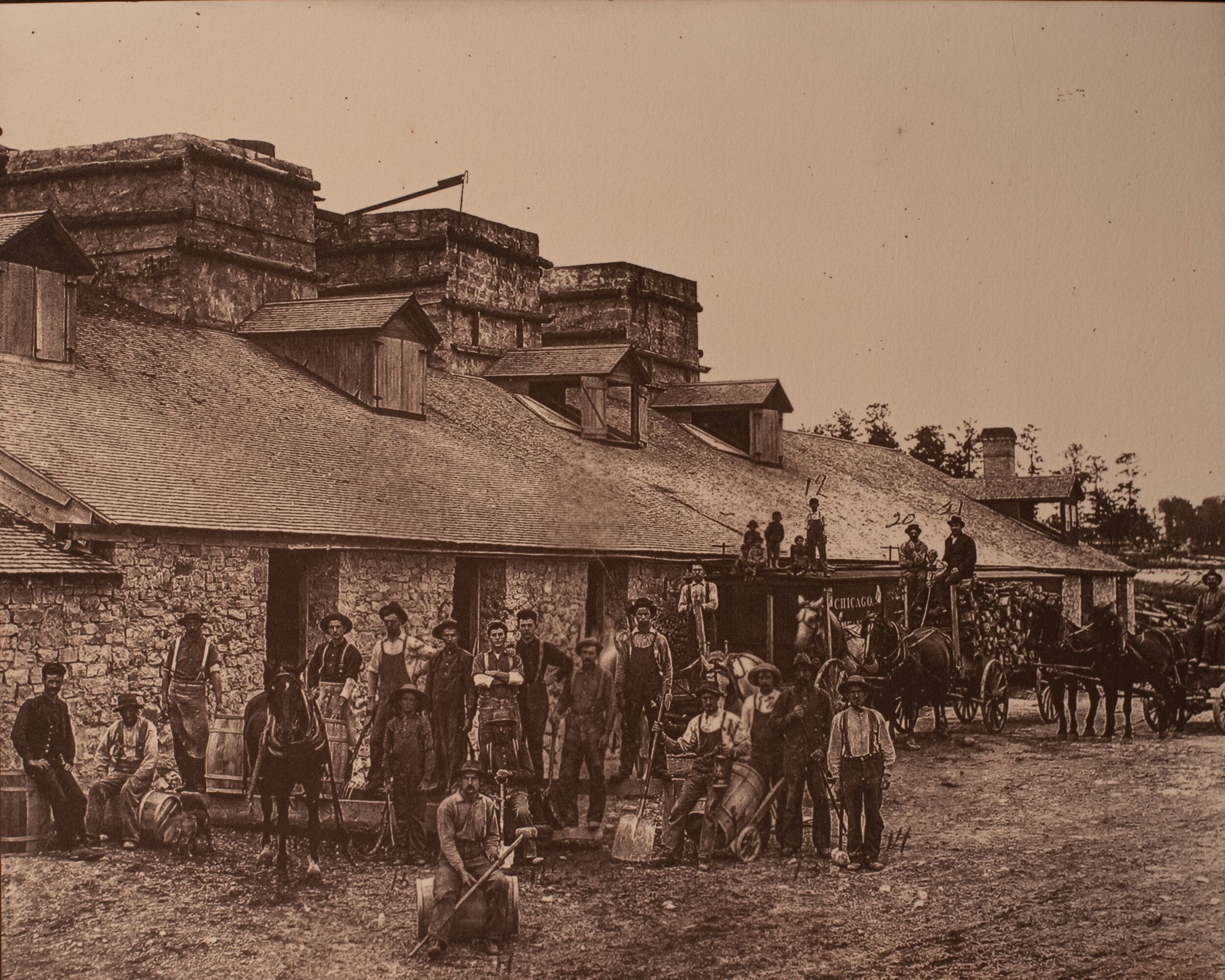

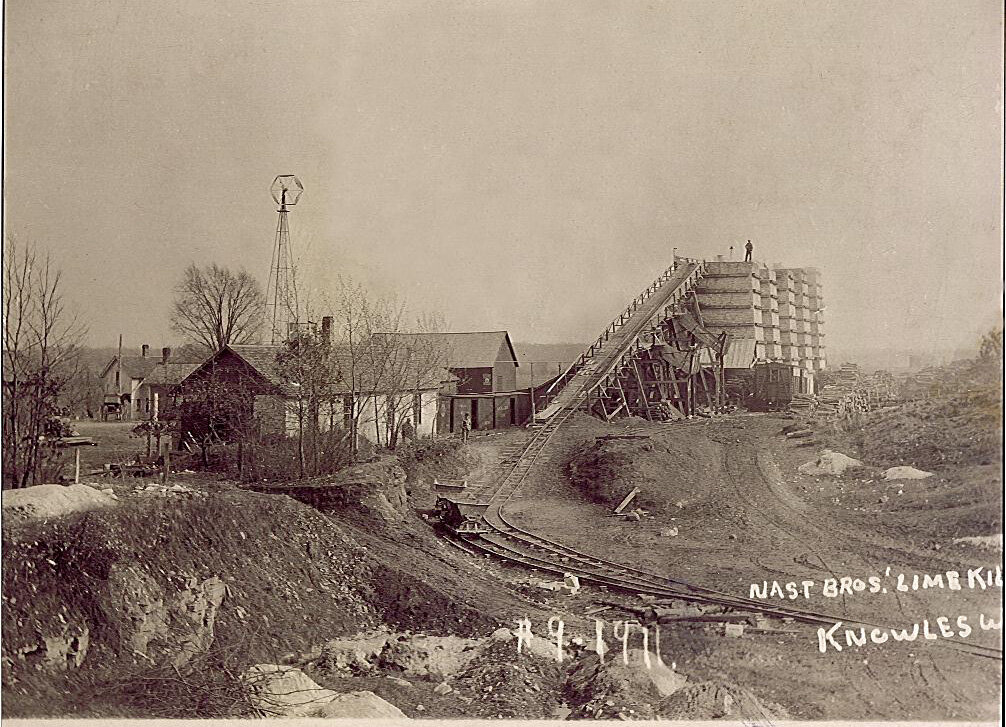

This image of the lime operations at Hayton, Wisconsin (Manitowoc County) is one of my favorite. Technically it is a well composed, well lit image that would appear to have been made with an 8x10 camera. The lack of motion blur would indicate that it was shot on dry glass plate negative. The original image was likely printed as a silver gelatin print. Whoever the photographer was, they had command of not only the technical aspects of photography, but also had a strong eye for composition.

The copy shown is here a hand printed Van Dyke brown copy. Van Dyke brown is one of many historical processes in use at the time the original was made. Versions of Van Dyke brown formulas are also know as brown or sepia images.i

My thanks to Joel Valle for allowing access to his vast collection of historic lime kiln pictures.

The date of this image is not known, but likely somewhere around 1900.

While the technical aspects of this image are interesting, what makes it stand out is the story it tells. This tableau is very similar in nature to the images one often sees of late 19th century lumbering activities in Wisconsin.

This picture shows the crew of the Hayton plant outside the lime room where lime fired from the kilns (background), was then removed from the kiln and stored in barrels for eventual shipment by rail.

These kilns were wood fired, and on the far left we see the horse drawn wagons loaded with wood destined for the kiln. The person driving the horses appears to be well dressed in a suit, and would likely be a manager or perhaps owner of the lime operations. Next to him is a small child, and on the nearby roof of a box car are several more children. One can speculate that the children are related to the person in the suit.

On ground level we see many of the workers accompanied by tools that likely reflect their role in the operation of the facility.

A couple of the workers appear to be wearing (leather) aprons, possibly indicating protection from the heat of firing the kilns or removing the cooked lime.

Two workers are holding shovels, probably used to scoop the cooked lime from the kilns into wood barrels for shipment. The wood barrels were moved on hand carts as depicted here,

A couple of the workers appear to be holding large mallets which were probably used to crush either raw lime stone into more uniform pieces for firing, or perhaps to crush larger pieces before placing into barrels.

There is likely a lot more information that can be gleaned from close examination of this picture What really draws me to this image is the story it tells about the workers who toiled in these plants. Their stories and images tell us just as much, if not more, that any photograph of an abandoned lime kiln ever could.